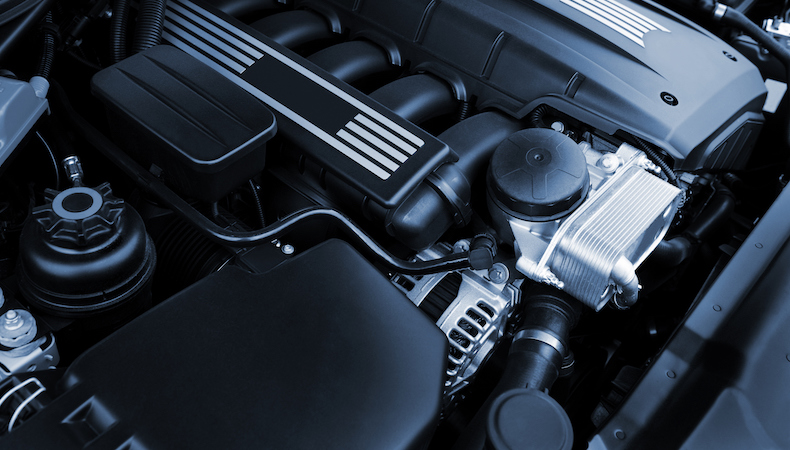

The automotive industry has grown tremendously over the past few decades, with new technologies driving more efficient production.

As such, precision plastic injection molding for components is becoming increasingly essential in the automotive space as manufacturers look to create higher quality and longer-lasting parts at a faster rate than ever before. At its core, plastic injection molding involves injecting liquid material into precisely designed molds using precise machinery.

Automotive injection moulders utilize innovative techniques to keep up with demand while ensuring tight tolerances for various vehicle components.

This blog post will provide an overview of automotive injection molding so you can better understand how this technology is revolutionizing contemporary car manufacturing processes today!

Pastic injection molding technology and how it has been used in automotive design

Plastic injection molding technology has revolutionized the automotive industry in terms of design and production. This technique injects molten plastic material into a mold to form various shapes and structures.

Plastic injection molding in the automotive world has allowed for the creation of intricate and lightweight parts that were once impossible with traditional manufacturing methods. From dashboard panels to interior trims, plastic injection molding technology has become a crucial element in the production of modern cars.

With the capability to create complex, yet precise designs, this technology has made it possible to produce vehicles with greater efficiency and lower costs. The benefits of plastic injection molding have impacted the automotive industry in a revolutionary way, by making vehicles better designed, more functional, and longer-lasting.

The advancements made in injection molding for automotive components

The automotive industry has always been at the forefront of innovation, and injection molding is no exception. Today, injection molding technology has made significant strides when it comes to creating complex, high-quality automotive components. With advancements in material science, it is now possible to produce intricate parts with incredible precision, accuracy, and efficiency.

Additionally, the integration of automation and robotics has streamlined the injection molding process, reducing production times and costs while improving the overall quality of the finished product.

These developments have allowed manufacturers to create a wide array of automotive components, from dashboards and door handles to engine parts and exterior trims, with unparalleled consistency and reliability.

The cost-efficiency and environmental benefits of plastic injection molding for automotive manufacturing

Plastic injection molding has proven to be an incredibly cost-efficient method for automotive manufacturing, providing numerous environmental benefits as well. With the ability to produce high quantities of parts in a relatively short time, manufacturers can drastically reduce their overall production costs.

Additionally, using plastic as a material for these parts presents a more eco-friendly alternative to traditional manufacturing methods, which often involve using metal or other non-renewable resources.

The advantages of working with a reputable plastic injection molding company

Working with a reputable company can make all the difference when it comes to plastic injection molding. Not only do they have the expertise and experience necessary to produce high-quality parts consistently, but they also have access to the latest technology and equipment.

A reputable company will prioritize communication with their clients to ensure their needs are met at every step of the process. Additionally, they will have strict quality control measures in place to ensure that every part meets or exceeds industry standards.

Ultimately, working with a reputable plastic injection molding company will save you time, money, and frustration by providing you with the best possible results for your project.

Specific projects that have been completed successfully using plastic injection molding

Plastic injection molding has been a game-changer for the manufacturing industry, as it allows for creation of complex and intricate shapes with ease and precision. Over the years, this process has been utilized in numerous successful projects, delivering exceptional results. One such project is the production of custom automotive parts, including intricate dashboard components and door handles.

The process of plastic injection molding ensures that each part is created with consistency and precision, resulting in parts that fit together perfectly and function seamlessly. Another project that has benefited greatly from plastic injection molding is producing healthcare equipment, such as prosthetics, surgical instruments, and medical device components.

With the ability to create parts with extreme detail and accuracy, this manufacturing process has improved the quality of care and saved countless lives.

From automotive parts to healthcare equipment and beyond, plastic injection molding has proven to be a reliable and efficient manufacturing method.

In summary, plastic injection molding is a powerful tool for automotive design. It provides detailed parts that are cost-efficient and improve environmental sustainability. Moreover, there are additional advantages to working with a reputable plastic injection molding company, including their ability to make complex molds and customization of components.

With their help, it is possible to produce high-quality parts while minimizing wastage and cost. These companies have proven their worth by successfully executing projects across the automotive industry, and case studies have highlighted the potential benefits of partnering with them.

If you want to take your automotive project to the next level, consider counting on an experienced plastic injection molding provider. They will help you develop a comprehensive plan that meets your specific needs while providing superior customer service throughout the process.